Mastering the Innovation of Data-Driven Services

Mastering service innovation in data-driven solutions requires overcoming challenges like strategic alignment, balancing goals, and managing risks....

Thrive with better data-driven decision-making for strategic choices, operational execution, continuous improvement and as-a-service.

The world is becoming increasingly dynamic and complex, which makes it harder to understand and predict outcomes of any system or process, let alone the impact of any interventions.

Thanks to new technologies we have a tsunami of data, which we could use for better analysis and predictions. However, we still struggle to collect the right data, turn them into actionable insights and to become more data-driven in our decisions.

In this article:

Recently, Yvo Saanen, Commercial Director and Founder of the TBA Group was guest in one of the Best Practices Meetings of the moreMomentum Services Community. The topic was “Managing Complexity Trough Digital Services”. This article is part of the output of this community event.

TBA Group serves global port, terminal and warehousing markets to optimise operations and automation and is part of Konecranes.

There are two major trends which make data-driven decision-making increasingly mission-critical for any type of business and function, including services in technology sectors:

This has a major impact on how we - and your clients - should take decisions, whether it is for:

VUCA is an acronym describing several aspects about the complexity of our world and industries:

The particular meaning and relevance of VUCA often relates to how people view the conditions under which they make decisions, plan forward, manage risks, foster change and solve problems. In general, an adequate view on these aspects shapes an organisation's capacity to:

The particular meaning and relevance of VUCA often relates to how people view the conditions under which they make decisions, plan forward, manage risks, foster change and solve problems. In general, an adequate view on these aspects shapes an organisation's capacity to:

Source of the above: Wikipedia

Already for quite a while we see an acceleration of the development of useable technologies, like:

At the same time, we see a major acceleration of the adoption of the digital technologies. Your clients, vendors, partners and competitors are becoming increasingly proficient in data-driven decision-making. This will change the way they work, compete, buy equipment and services and who they choose to work with.

Mid 2020 we did a global research amongst service leaders of 94 companies about their views and approach around Covid-19 and digital services. This confirmed our experiences that the adoption has got a major boost during the Covid Pandemic. Below is one of the graphs from the report “Innovate your way out of the Covid-Crisis”

Too often, decisions we make do not take into account the complexity and unpredictability. As a result, we take wrong decisions leading to lack of improvement, missing opportunities and maybe even making things worse.

If we recognise the decision was wrong, we may correct and try again. This could become rather expensive trial-and-error with:

Making more of these critical decisions based on the right data, insights and models, will allow you to analyse and test new solutions in a safe and controlled environment, taking away many of the risks and cost of wrong decision.

Many companies, including manufacturers and their clients, struggle to build the necessary capabilities and be proficient in data-driven decisions. For example, they:

The essence of data-driven decision-making is to use data to better:

This can be for any kind of decision, whether it is about a new strategy, designing a new service, process or system, improving these or adjusting these for new applications or events.

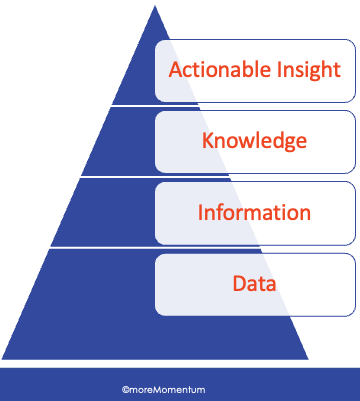

Data is available in heaps, there is so much data available that we actually do not know how to find our way around it, nor how to really get something out of this data. Often, these data are coming from complex systems and processes, with many variances and interdependencies, making it even harder to discover valid patterns and relations. The data itself is not what provides us with value. We need to create structures for analysing data to get actually value out of it.

So, we need a process to bring us from data to information, knowledge and actionable insights; we need modelling. We use data to build a model of a current situation and/or an envisioned situation that can predict future behaviour.

So, we need a process to bring us from data to information, knowledge and actionable insights; we need modelling. We use data to build a model of a current situation and/or an envisioned situation that can predict future behaviour.

A model is a simplified representation of a reality, which allows us to come to very good conclusions about a topic we want to make a decision about. A model is always an approximation of the real system. A model is not the real system.

A model could be anything between:

Simplification, or reduction is key to address complexity of a system or process. Reduction in the context of modelling means that we:

Only that way we get a useful and valid model of the reality that contains enough level of realism to represent a good basis of decision-making.

Although, simplification sounds like a simple task, it actually is pretty hard work and requires a deep understanding of data, modelling and the real-life system you are modelling.

Data-driven decision-making = Modelling with data

There are various ways how data-driven decision-making with models can improve your decision, like:

Most systems and operations have a rather dynamic behaviour in which many elements show a variation in characteristics like frequency, duration and complexity. For example:

The more elements and the more variations in a system or process, the more complex it is to identify critical paths, root causes of an issue and to take the right decisions to operate and to improve.

Once you have identified a few options how to act or improve a system or process, you will not be 100% sure which option is the best and how well the different options will work out. So, an often-used approach is trial and error: test and pilot in real-life situations and try to get feedback as quickly as possible, to avoid unnecessary negative consequences.

The quickest, safest and most affordable way to try and fail fast is to start testing in a simulation or model. Here you can try different scenarios, fine-tune the solutions, assess the risks and gain confidence before implementing the solutions.

Fail fast, learn fast in a safe and low-risk environment!

Every now and then you are preparing for this unique, extreme event, which you need to get right the first time. Think about how a flower auction can prepare a process improvement for Mother's Day or Valentine's Day where everything will be tested to the extreme. There is no way to test this live. These are once-in-a-year opportunities and failure is not an option for those days.

In a safe model environment, you can develop and test different scenario’s time after time until you are satisfied with your solutions. You will better understand critical factors and will be better prepared for unexpected situations during such event.

Most of us struggle to really understand more complex processes with many variances and interdependencies. A process simulation and visualisation can help us better understand the process, how different parts interact and how the process will react in specific circumstances. This will enable us to better analyse current behaviour, find new solutions and test them in a visual way.

A very important benefit of using models and data to drive decisions is that you can test scenarios of the current process, as well as alternative solutions to improve performance to see which solutions have the best impact.

This allows you to prioritise the alternative solutions, quantify the impact of the chosen solution and justify this against the resources to invest and the potential disturbance from the implementation project.

One of the biggest enemies for adequate decision-making is making assumptions that are not tested. We assume a lot about our businesses, operations and systems, how our clients work and how “best practices” work.

The modelling, which goes hand in hand with data-driven decision-making, is very useful to increase our understanding and avoid guessing:

In the services business of manufacturers, there are several ways to create value from data and data-driven decision-making:

The opportunity here is not only to increase the value of existing services (for example higher uptimes or less unplanned downtime through predictive maintenance), but also to offer services at a lower price (with the same margin) and expanding the scope of your services and hence increasing your relevance for clients.

A couple of examples are:

Generating additional revenues from digital services is easier said than done. Quite a few manufacturers struggle with this and see their service development stagnating or not picking up momentum.

Data analysis can help you solve a couple of critical challenges:

The name of the game today is “adapt or die”. All companies are on their journey of a digital transformation and are becoming more proficient with data-driven decision-making. This has been the case for years and is now significantly accelerating due to COVID.

Also your clients are changing the way they operate. They will be looking for service providers for running and developing their data capabilities.

System integrators and digital-native service providers are on the fence too. They are entering your industry with advanced digital and data-driven solutions and will become your new competitors (or partners). A few examples:

The competitive landscape will change dramatically:

This could lead to disruption of the services business in the true meaning of disruption - market disruption. Some players will lose their market position, struggle to reap the benefits of the new growth opportunities, while others will steal away the new opportunities and thrive.

There is a unique and critical opportunity for manufacturers to be a leading player in this transformation of their industry. Which at the same time is a critical threat for the laggards.

Manufacturers can only thrive during the digital transformation when developing strong data and digital capabilities, becoming more data-driven in their decision-making and advancing their customers’ solutions.

Subscribe for the our Impulse Letter

With regular updates about service news, trends and best practices.

Mastering service innovation in data-driven solutions requires overcoming challenges like strategic alignment, balancing goals, and managing risks....

In a dynamic business landscape like in services for manufacturing companies, strategic thinking is a necessity. Cultivating this skill across all...

Navigating the evolution of data-driven services requires understanding key patterns and embracing innovation. Learn about the journey from concept...